How we help MEP Centers

MEP Center Partnerships to Drive Client Count and Company Impact

The Business Excellence Group is an organization that partners with MEP centers to drive impact for the MEP center and their clients. We have over 30 years of direct MEP center management experience, as well as over 100 years combined experience in business and operations management, Lean, supply chain management, and human resources. We provide methods, products, and services to optimize your center and client’s business. We can act as the 3rd party provider to consult and educate your manufacturing clients or support your center operations to get 10/10 on your scorecard. Here are the ways we can partner:

1. Train-the-Trainer/Certifications

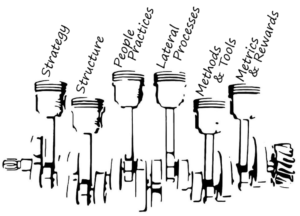

The Business Excellence Group’s methods optimize a business and its products to ensure it is aligned to the strategy no matter if it is to start up, scale to new demand, or position for sale. Optimizing the organization is the outcome of the Business Excellence Optimization Model. When used it identifies the “pain points” in a company, it creates an improvement plan, develops predictable impact, and helps the company achieve their strategy and goals. Below are ways that MEP centers can be certified in the tools of the Business Excellence Optimization Model.

Business Excellence Optimization Assessment Process

This program teaches MEP center staff on how to assess a company, develops an improvement plan, and partners with clients to implement a sustainable system to help the company to grow and meet your company’s strategy. The Business Excellence Optimization Assessment identifies areas to improve that align to the Straight6™ Model.

Core 8 Materials

- Strategy: Optimizing the Organization “Take it to Ten”, Strategy to Action, Creating a Business Transformation

- Structure: Aligning Structure to the Achieve Strategy, Single Point Accountability and Decision Making

- People Systems: Optimizing Leader Performance

- Lateral Processes: Optimizing Tactical Performance

- Metrics: Transformational Performance Metrics

Supply Chain Materials

- Fundamentals of Supply Chain Management

- Proficiency in Supply Chain Management

- Understanding Total Cost of Ownership

- Total Cost of Ownership Reduction (includes a simulation and TOC calculator)

- Vendor Negotiations

- Vendor Contracting

- Assessing Supply Chain Risks

Workforce Development Materials

- Assessing and Hiring Talent

- Onboarding and Training their new hires

- Managing the Performance of the whole person

- Growing Capability through Goal setting and quarterly evaluation system

- Career and Compensation Growth

- Succession Management and Planning

2. Center Operations Consulting

The Business Excellence Group is comprised of a team that has extensive MEP and industry experience. Our mission is to help strengthen and grow MEP centers around the network to exceed the expectations of NIST MEP while creating a revenue stream that is independent of any state or federal funding. The Business Excellence Group leverages their center operations experience to consult MEP centers to meet the big 3 core metrics: company count, center revenue, and most importantly client impact. We do that by providing the services in the following areas:

Center Operations Consulting – this could be anything from helping implement a new business model, to providing sales training, to helping expand the center capabilities.

Operating Systems Support – the Business Excellence Group has information systems programming and customization experience. We have helped centers use Salesforce as a tool to manage center operations. We have provided custom coding, the creation of dashboards for center management, as well as the collection of and customization for predictive impacts.

Center Strategy – We help MEP centers identify what they need to do as a business to achieve the big 3 core metrics. We conduct a strategic planning process that helps optimize an organization’s performance to achieve their objectives. We look for gaps in the organization’s structure, people systems, lateral processes, tools and methods, and metrics, and work with the organization’s leadership to close those gaps. When this part of the analysis is complete the leadership team has strategic objectives and the gap closing actions regarding the what, who, and how they will achieve it. This is then what the MEP center will focus on during the next 18-36 months.

Center Organizational Design – Once the center has determined their strategy and goals, the Business Excellence Group will work with the center leadership team to define the necessary organizational structure to achieve the strategy. When people work within the organization’s structure, they need clarity of how they align to the strategy. They need to know that their work enables the organization to meet its goals and ultimately the strategy. The company needs good systems to attract, grow, and retain their people and talent. In this phase, the Business Excellence Group will work with the center to develop clear position expectations. In order to attract, retain, and grow talent it is important to know what the appropriate compensation structure is to use. The Business Excellence Group will leverage salary data to build the salary bands for each role. Using this data, the center will have a true equivalent by role to measure appropriate compensation for entry level, mid-level, and advanced level pay for each center role. This data combined with the role design can help identify career pathways for those individuals that want to grow their capability and to advance within the center.

3. Content House (Material Licensing)

The Business Excellence Group has developed a number of programs/products that are available to MEP centers for use. These programs include:

Strategy

- Optimizing the Organization “Take it to 10” – How to create a strategy.

- Strategy to Action – How to put your strategy into action to create a plan and how to execute the plan.

- Creating a Business Transformation – How to manage change.

Structure

- Aligning the Structure to Achieve the Strategy

- Single Point Accountability and Decision Making

People Systems

- Optimizing Leader Performance – leader standard work

- Role Design – creating clear accountabilities, responsibilities, and metrics

- Creating a quarterly evaluation plan with corrective actions

- Compensation modeling – look at statewide data and create compensation bands for individual roles and career pathways

Lateral Processes

- Optimizing Tactical Performance – How to implement huddles and constraint operations (this is a powerhouse for production – we usually see a 20% improvement in cost, quality, output, and moral)

Methods and Tools

- Lean Manufacturing

- Value Stream Mapping

- 5S

- Standard Work

- Set-up Reduction

- Kaizen Events

- TPM

- Materials Management – Kanban systems, inventory controls, production schedules

- Quality systems/tools – Six Sigma, DMAIC, SPC, FMEA, DFMA, Fishbone/Cause and Effect, ISO

- Training Within Industry (TWI)

Metrics

- Transformational Performance Measures – Creating a set of performance metrics that run from the strategy all the way down to the individuals

Supply Chain

- Supply Chain Strategy/Supply Chain for Leaders

- Fundamentals of Supply Chain Management

- Proficiency in Supply Chain Management

- Understanding Total Cost of Ownership

- Total Cost of Ownership Reduction (includes a simulation and TCO calculator)

- Vendor Negotiations

- Vendor Contracting

- Assessing Supply Chain Risks

People Systems and Workforce Attraction/Retention

- Assessing and Hiring Talent

- Onboarding and Training their new hires

- Managing the Performance of the whole person

- Growing Capability through Goal setting and quarterly evaluation system

- Career and Compensation Growth

- Succession Management and Planning

4. Third Party Delivery Resource

The Business Excellence Group can support MEP centers in the delivery of services. We can provide support in providing direct delivery as a contractor, provide connections to other delivery resources as a resource broker, or provide sales training and sales support. All of these services are available based on the services listed in the above section.

To read our most recent MEP newsletter click here.

Testimonials

“We chose a holistic optimization model instead of tuning up bits and pieces of our business. This approach has prepared us for growth as we serve the Oklahoma manufacturing community…”

They are incredibly accommodating and knowledgeable about how centers should operate, and their coaching has been excellent…”

Alyssa Rodrigues, Ph.D, Director